We first embraced the concept of dry management for coal combustion residuals in 2008. Projects of this scope and size require many years for design, planning, permitting, contracting, and execution. As a result of our early transition in this direction, we’re in the final stages of our plans.

- We operate dry CCR handling processes at all of our coal-fired power plants.

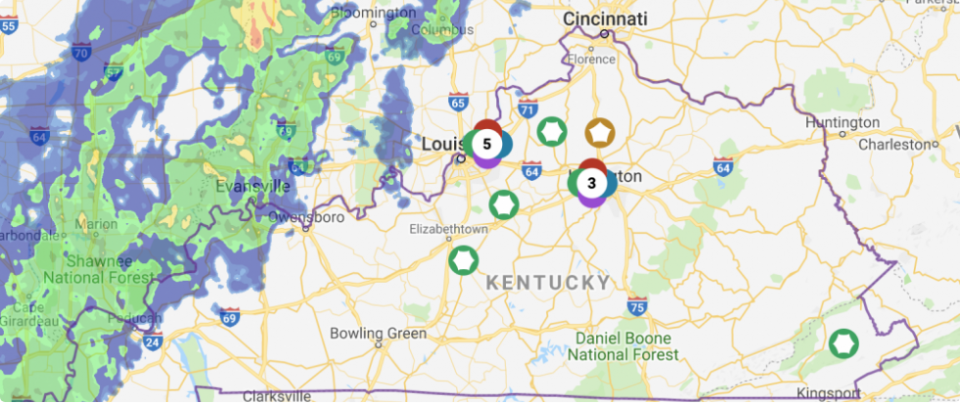

- We operate dry storage systems at our Mill Creek, E.W. Brown, and Ghent power plants. Our newest dry storage facility at Trimble County will become operational in 2022.

- Once processed, the dry CCR materials are managed on site at our power plants, if not beneficially used offsite for materials such as concrete, wallboard or fertilizer.

- As part of our extensive plans and in compliance with the U.S. EPA’s Effluent Limitation Guidelines, we operate new, state-of-the-art process-water treatment facilities – using physical and chemical-based technologies. We’re in the process of also adding biological treatment systems over the next several years to further treat water before leaving our power plants.

We coordinate the sale of our CCR by-product materials to third-party companies for their production processes.

Since 2003, nearly 27 million tons of CCR materials generated at our power plants have been beneficially used to make products like concrete, cement, porcelain tile, wallboard, fertilizer and roofing shingles.

100% of the revenue generated through these sales goes back to our customers as a credit primarily calculated into the environmental surcharge on bills each month. Since 2016, beneficial use has generated more than $42 million in savings for LG&E and KU customers.