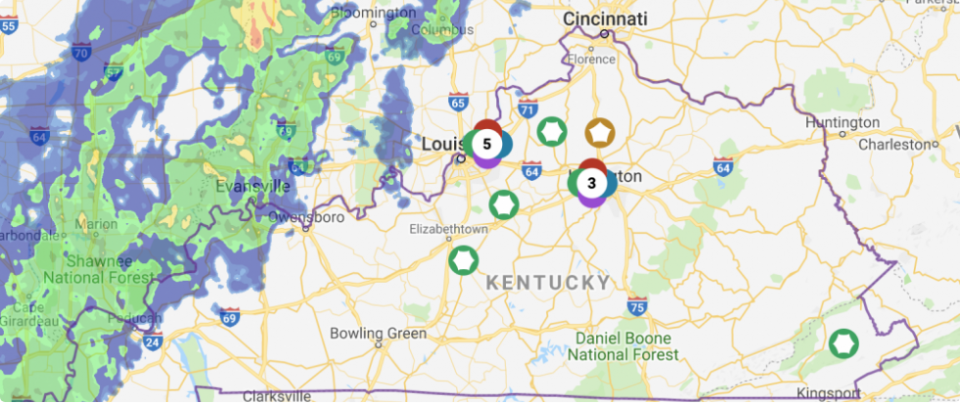

Mill Creek 5, a 645-megawatt natural gas combined-cycle generating unit, is now under construction and expected to begin powering customers’ homes and businesses in 2027.

Mill Creek 5, which will be LG&E and KU’s most efficient and advanced generating unit, was approved in 2023 by the Kentucky Public Service Commission as the least cost approach to the utilities’ generation investment plan, which also includes adding a significant amount of new solar, a 125-megawatt battery energy storage system and the company’s largest number of energy efficiency programs in its history.

From new factories and housing developments to high-tech facilities like data centers, learn more about how we’re powering Kentucky’s growth.

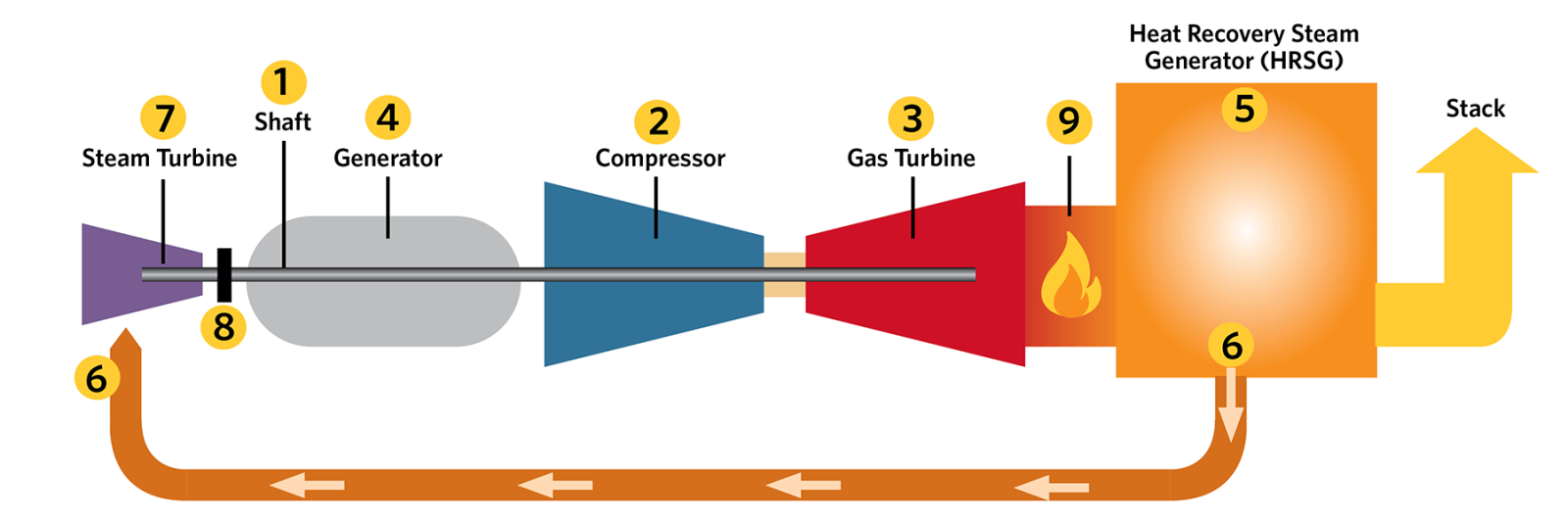

Mill Creek 5 (MC5) is a very complex generating unit that will produce electricity through both a gas turbine and a steam turbine. Here is how it will work.

- An electric motor starts the rotation of the gas turbine/generator shaft (1) that extends the length of the unit.

- The shaft facilitates the suction of air into the compressor (2) via its rotating blades.

- Natural gas combusted between the compressor and the gas turbine (3) heats that air, which then expands as it exits the turbine. This causes the shaft to rotate with greater force. (The electric motor then stops running.)

- This force is transferred to the generator (4) and converted to electricity for our customers.

- The hot air exiting the gas turbine in Step C enters the Heat Recovery Steam Generator (HRSG) (5) that heats the steam, which flows (6) to and rotates the steam turbine (7).

- The rotating steam turbine shaft (8) then couples to the gas turbine/generator shaft (1) at a clutch mechanism providing more energy to the generator. Capturing the energy from otherwise unused exhaust heat increases the efficiency of this unit from 43% to 64%.

- Mill Creek Unit 5 will be the first unit in LG&E and KU’s fleet to use duct firing at times of peak energy demand. Duct firing adds heat in the duct work (9) between the gas turbine and the HRSG. That provides more steam to the steam turbine, enabling it to generate more energy.