Employees remotely operate battery at E.W. Brown Station.

LG&E and KU Energy operates Kentucky’s first and largest utility-scale energy storage system — a 1-megawatt, 2-megawatt-hour lithium-ion battery. The battery is co-located with E.W. Brown Solar, allowing the company to explore how batteries can improve the inherent intermittency of solar power.

The battery, which is always charging or discharging and continuously collecting data, has provided immense operational and safety improvements, and contributed to academic research.

Daily operation

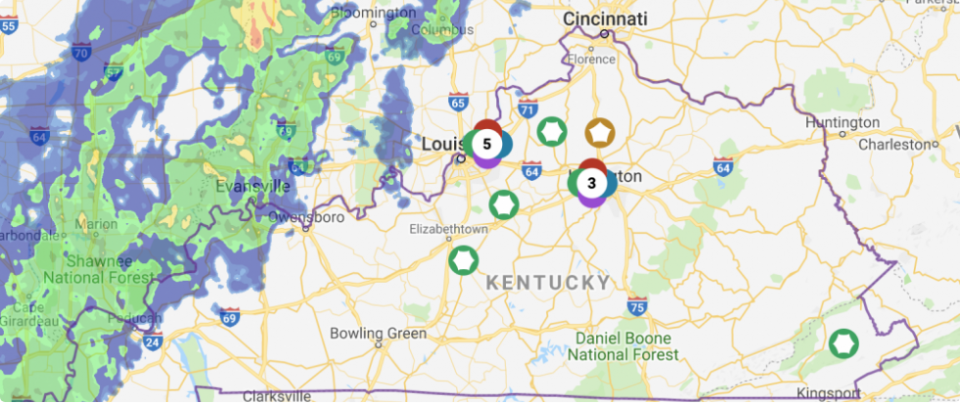

LG&E and KU employees operate the battery 24/7, 365 days a year, from Louisville — typically charging during the day when solar power is available and discharging at night. The battery is capable of performing solar-supporting functions during the day, including power smoothing and peak limiting. According to Aron Patrick, manager, Technology Research and Analysis, the TRA team also has been testing advanced battery functions. “Some of these functions include ‘volt-var support mode,’ during which the battery supplies or absorbs reactive power in order to maintain grid voltage at a reference value,” Patrick explained. “The team also has tested ‘frequency-watt mode,’ in which the battery rapidly charges or discharges to reduce grid frequency variation. Understanding how the battery works with the availability of solar power will help us better plan for variable power with our system.”

Operational improvements

The TRA team developed a real-time battery performance dashboard to monitor the system and maintain awareness of hundreds of conditions remotely. The team also developed an alarm system, capable of emailing and texting staff to alert them immediately about potential problems at the battery site. Five trained employees now rotate responsibility for operating, monitoring and maintaining the system, and all are capable of responding to problems at the site.

Battery use and availability has improved — from 54% in 2018 to 89% in 2020, as shown in the graph below. The battery has collected twice as much data and stored almost twice as many megawatt-hours in 2020 as any other year.

Safety

The TRA team conducts global benchmarking about the batteries and adjusts operations accordingly, with an eye on safety. Consequently, since June 2019, the company has implemented numerous changes for safety improvements.

- Installed danger signs on the system, fences and gates surrounding the facility and established a 75-foot safety perimeter around the battery.

- Brought the Korean manufacturer, LG Chem, to the site to conduct an inspection, upgrade the software and supervise a system restart.

- Contracted for a formal independent safety audit, completed in August 2019.

- With third-party safety contractor, Benson Fire, conducted a first responder and plant operator battery fire training day in December 2019.

- Developed an emergency response plan for Brown plant operators and all local fire departments.