(LOUISVILLE, Ky.) – March 18 is Natural Gas Utility Workers’ Day in the U.S and Louisville Gas and Electric Company is marking the day by highlighting just a few of the hundreds of employees who help keep the natural gas safely flowing 24 hours a day, seven days a week, 365 days a year.

Gas Control Center

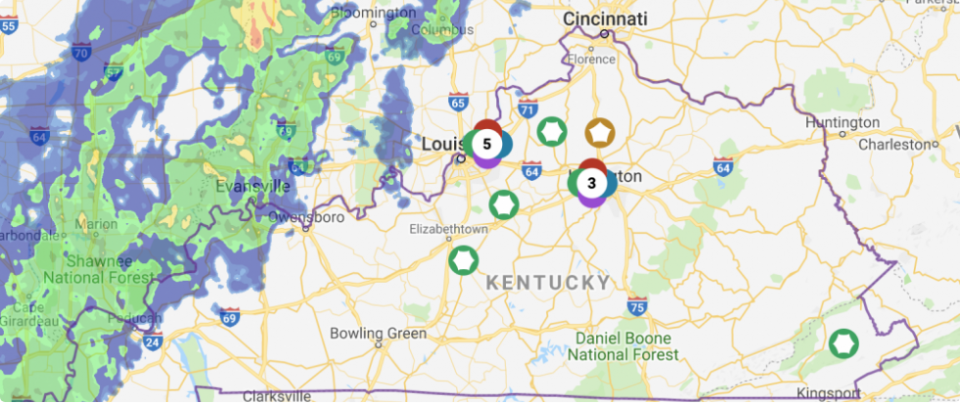

LG&E serves 335,000 natural gas customers and maintains more than 4,000 miles of transmission and distribution lines. The entire system is monitored round the clock from the company’s Gas Control Center.

“At 4 a.m., we start to forecast the upcoming gas day and figure out what’s needed based off of historical data and upcoming weather and temperatures,” said Robert Reeder, gas control operator. “We start to get a plan going with what we purchase and what we’re going to need to supply safe gas to the customers.”

Reeder has been an employee at LG&E for 10 years. His responsibilities include managing the high-pressure gas system for Louisville and the surrounding area, along with managing the company’s four natural gas storage fields.

LG&E works year-round to secure competitively priced natural gas supply for customers and takes advantage of its underground storage facilities to inject typically lower-cost natural gas in the summer months.

Additionally, LG&E's natural gas storage helps meet customer demand through the winter months by supplementing pipeline supplies when wholesale natural gas is typically more expensive, which can help stabilize prices for customers.

System Regulation and Operations

LG&E’s system undergoes regular inspections and maintenance throughout the year to help maintain reliable service for its customers.

“We maintain everything on the high-pressure system for all the manual regulators. We do all the required maintenance and inspections to make sure everything is safe and operating correctly,” said Rocky Lewis, system regulation and operations technician. “Everything we do you have to stay extremely focused. If you shut the wrong valve or open the wrong valve, it has huge consequences on the system.”

Lewis, a 12-year LG&E employee, and his department also work together with the Gas Control Center to troubleshoot any problems that occur on the system.

Corrosion Control

LG&E’s steel pipelines that supply natural gas to homes and businesses undergo annual corrosion testing to help protect the system and prevent potential leaks.

“We have to go to these test stations every year and we take a voltage reading, and it’s got to be within a certain range,” said Joe T. Hamilton, corrosion technician. “We don’t want leaks of any type because that’s obviously going to be an emergency situation.“

Hamilton has been with LG&E for more than 18 years. His team performs roughly 17,000 corrosion inspections per year.

Gas Meter Shop

Gas meters on customer’s homes and businesses also go through vigorous testing at LG&E’s gas meter shop before they are installed.

“I think that customers would be really surprised at how much actually goes into the testing of these gas meters and what we do behind the scenes to make sure these meters are accurate,” said Tim Bowles, prover. “We test every meter that comes out of here. They must be within a certain tolerance before they can go out and be installed. Every cubic foot of gas that goes through this meter has to be measured and has to be billed properly.”

To learn more about all the ways LG&E works to provide safe and reliable service to its customers, visit lge-ku.com/safety/gas.

###

Louisville Gas and Electric Company and Kentucky Utilities Company, part of the PPL Corporation (NYSE: PPL) family of companies, are regulated utilities that serve more than 1.3 million customers and have consistently ranked among the best companies for customer service in the United States. LG&E serves 335,000 natural gas and 436,000 electric customers in Louisville and 16 surrounding counties. KU serves 545,000 customers in 77 Kentucky counties and 28,000 in five counties in Virginia. More information is available at www.lge-ku.com and www.pplweb.com.